How To Optimize Inventory Using Weekly Data

Inventory Forecasting Guide

Poor inventory forecasting can accept a deadening, less obvious impact on your business organisation, silently chipping away at your margins, reputation, and customer satisfaction levels.

That'due south why it is necessary for any business owner to master the fine art of forecasting.

Learn how to manage this sometimes overlooked and very challenging surface area of whatever business concern managing inventory.

Then, what do you want to learn?

- What is inventory forecasting?

- five benefits of accurate inventory forecasting

- four inventory forecasting methods for demand planning

- How to forecast inventory in iv steps

- Tools for inventory forecasting

- How ShipBob tin help with inventory forecasting

Request Fulfillment Pricing

Let'southward talk. Our experts can help you boost your guild volume by xxx% year over year.

A fulfillment expert will get back to y'all presently.

What is inventory forecasting?

Inventory forecasting is the process of computing the inventory needed to fulfill hereafter customer orders based on how much product you predict y'all will sell over a specific menstruation of time. These estimates accept historic sales data, planned promotions, and external forces into account to exist as accurate as possible.

Main differences between inventory forecasting and replenishment

With so many inventory terms, it can exist difficult to empathise the nuances, especially when they get hand in hand.

- Inventory forecasting is an ongoing procedure that helps brands understand future demand by taking historical data, seasonality, and external factors into account.

- Inventory replenishment on the other paw, is the human activity of reordering more inventory from a supplier or manufacturer to get more stock.

In other words, ane outcome of accurate inventory forecasting is enabling the timely replenishment of products.

How does inventory forecasting work for online stores?

Inventory forecasting can sound similar an intimidating concept, and information technology'south often easier said than done. Fortunately, ecommerce brands can start pocket-sized to get a better grasp on their sales and supply chain — without a team of data scientists or the resources of a large corporation.

It all starts with tracking the data automatically — not manually — using inventory direction software. If you work with a 3PL similar ShipBob, these tools are congenital-in. The procedure doesn't accept to be a big lesson in statistics — merely an practise in bringing together multiple data sources to make educated guesses.

Implementing inventory forecasting into your current workflow can profoundly benefit your unabridged performance and help your ecommerce shop run leaner, prevent stockouts, and improve cash catamenia.

The top v benefits of authentic inventory forecasting

Now that you understand the downside and potential negative impact of not having a system in place for proper inventory forecasting, here is the upside of getting it correct.

i. Less inventory needed on hand

You tin can shop inventory in majority in a warehouse and take it sit there collecting dust, but that'south non usually a profitable style of doing business. By having data-driven predictions on how much inventory you volition demand, you won't have to purchase inventory that you don't need for a given fourth dimension period. This ways you can improve inventory accounting, assist your cash flow, and even free up funds for other areas of the business.

"With ShipBob, nosotros have access to live inventory management, knowing exactly how many units we have in each fulfillment center. This not only helps with our overall process in managing and making sure our inventory levels are balanced but also for tax purposes at the end of the year."

Matt Dryfhout, Founder & CEO of BAKblade

2. More sales from fewer out-of-stock items

If you have enough inventory on hand, you don't accept to worry about stockouts or back orders — y'all can fulfill each order equally before long as information technology's placed and provide customers the commitment they were promised. Aligning with marketing on upcoming campaigns (even at the channel-level) is critical for inventory forecasting.

Additionally, the customer feel remains a positive one when shoppers find what they're looking for online and don't encounter an "out-of-stock" message but to leave your store and shop elsewhere. For every client yous lose by non having what they need when they need information technology, you risk losing their future business equally well.

iii. Less manual labor

Accurate inventory forecasting saves labor and warehousing costs considering you lot are better prepared to handle changes in demand and tin can reduce some manual piece of work. Inventory forecasting tools aid automate reordering, predict labor needs, and account for changes in society book, making it piece of cake to sympathise what'southward coming and reduce inventory carrying costs. This saves fourth dimension and manpower for warehouse management and all staff.

4. More efficient production cycle

Inventory forecasting helps y'all manage products amend across the entire retail supply chain. When you know your manufacturer'south atomic number 82 times, your warehouse receiving timelines, and the verbal stock levels for each production that you need to brand a new buy social club, y'all can work more efficiently with your supplier and gain a better agreement of production cycles.

This way, it'due south non a guessing game or just ordering more inventory in one case it seems like you're running low. You lot can brand informed decisions and eliminate the demand to expedite production schedules and shipments.

"Our B2C and B2B order volume changes month to month. Betwixt shipping new collections for wholesale earlier in the twelvemonth and Q4 madness for direct-to-consumer sales, nosotros've been able to get through our heaviest seasons while staying alee of production using ShipBob's forecasting tools — even as order volume more than than quadrupled in a twelvemonth."

Ryan Casas, COO of iloveplum

5. How inventory forecasting helps reduce inventory waste

Dead stock is inventory that's no longer sellable. Most ofttimes, this is due to information technology beingness expired, obsolete, or out of season — all causes that typically stalk from poor inventory forecasting.

Over-ordering inventory in the first identify is a mutual offender, potentially from having a high minimum order quantity from a manufacturer. Simply more often information technology'south miscalculating future need or lack of tracking this diligently altogether.

Of class, not all SKUs are created equal, or more specifically, demand tin vary greatly for every product you sell. Knowing your best-selling inventory vs. your tedious-moving items can help you make better decisions virtually the product life cycle, which tin even lead to simplifying your production line by retiring unsuccessful products (working closely with sales and marketing teams on understanding which products you want to deplete or run a flash auction on).

4 inventory forecasting methods for demand planning

In that location are a few inventory forecasting types to exist aware of that aid in demand planning. They tin can and should be mixed and matched to help predict potential outcomes, as each inventory forecasting type has a different use case or focus.

1. Quantitative forecasting

This model of inventory forecasting uses historical sales data to conceptualize future sales. The longer the business or products have been around, the better the information prepare and analysis volition be. You demand at to the lowest degree a year of sales to see whatsoever seasonal trends, but several years of data is even more than meaningful every bit information technology will help identify true consistency and annual patterns.

In the nautical chart below, y'all tin can see overall demand for one brand over a ii-year period. Their monthly order volume can fluctuate up or downward by approximately 1,000 orders in either direction. Because it'south not a directly line going up and to the right, they'd benefit from keeping extra safety stock bachelor for the busier months.

This make has had steady growth and increased demand by roughly 3,000 orders per year. They can use their historical information to help estimate what to await in the futurity.

two. Qualitative forecasting

This model uses less data from the merchant'due south club history and instead relies on external factors similar market place intelligence, ecology forces, economic demand, and other macro-level shifts (e.yard., buying behavior shifts from pre- to post-pandemic, aggrandizement, etc.). Qualitative forecasting oftentimes uses expert judgment like an analyst, and isn't necessarily a task to exist performed by merely anybody.

three. Tendency forecasting

This inventory forecasting type involves keeping a close eye on sales trends in your product line over time to help indicate bigger picture changes — non just seasonality — but broader shifts in consumer buying behaviors.

While you can't always predict the next product or category to disrupt your business, looking at the post-obit tin also help yous stay ahead of the game:

- Trends on TikTok (not necessarily the latest dance craze but keeping a pulse on content posted to the most-downloaded app in recent history, which has made many products become viral)

- What VCs are investing in over fourth dimension (non a few years ago)

- Regulations and legislation impacting your products or products that complement or supplement yours

- Demographics and generational shifts (e.g., as Gen Z gains more purchasing power, where are they gravitating towards with purchases?)

- Geographical impact (how your customers' aircraft destinations change over fourth dimension, and how buying behaviors vary at the country, land, and city levels)

Another key piece of information to incorporate is your customer lifetime value (LTV). You lot tin get granular and analyze trends across different combinations of SKUs:

- Do customers buy the same items from you more than once?

- Are customers buying multiple items from you each time they place an order?

- Which products are ofttimes purchased together?

As yous larn new customers, yous may be able to anticipate any repeat purchases using this information. Monitoring which products are purchased together can help you understand your customers' behavior and even aid yous make up one's mind how to group your products for new offers or promotions. Yous may even find patterns of how one SKU affects or drives demand for another.

For example, if yous sell razors and dissever bract cartridge refills, what'southward the ratio of blades to razor sold? Does that amount continue to increase over time and extend the lifetime value of a customer? Whatsoever type of recurring revenue or subscription-based purchases can aid with inventory forecasting.

iv. Graphical forecasting

With an intuitive name, graphical forecasting helps visualize data to identify patterns that may accept gone unnoticed as manifestly text. It can be used on whatsoever of the information sets higher up to generate trend lines, observe discrepancies, quickly compare variables, and much more.

For example, below is a chart of a highly seasonal brand that experiences incredible demand during i role of the year and virtually zero orders the rest of the year, comparing shipments per month and the month. Their inventory forecasting will exist very dissimilar from a brand with consistent demand or gradual growth.

How to forecast inventory in 4 steps

There are many factors that piece of work together and assumptions to make to predict demand in both the well-nigh and long term. Acquire how to forecast inventory by using our simplified version below.

Note: At that place are much more than scientific methods and advanced statistical models to develop, just for ecommerce businesses that desire to put something basic into practice, this stride-past-step guide walks through the factors needed to accurately forecast inventory on a small scale.

1. Choose a forecast period

A forecast period is the length of time used to determine the exact inventory quantities you lot'll need to social club. To get a sense of seasonality, an annual view is helpful, but you tin as well cull weekly, monthly, or quarterly.

ii. Identify trends

Now that you've established your timeline, it's time to analyze the data. To get a benchmark from the raw information:

- Annotate whatever outliers that won't apply to the time to come demand menstruation (e.g., if your make went on Shark Tank or Adept Morning America and received a large spike in orders immediately following the circulate, or had a major proclamation such as a funding round or acquisition).

- Review seasonality and promotions y'all ran.

- Wait at geographical growth (e.chiliad., pay attending to whether yous're organically getting international orders and to what countries).

- Wait at how this changed from past periods (east.g., if you cull a full agenda yr as your timeline and have been in business for several years, consider looking at the prior year likewise).

iii. Forecast the upcoming menstruation

If you're comfy with the baseline yous got from the previous flow, map out your futurity plans as you lot look ahead to understand demand.

- Review upcoming marketing plans (announcements, promotions, new influencer campaigns, etc.), including what's like and different from the prior period (due east.1000., Facebook ad effectiveness taking a hit from recent iOS updates).

- Incorporate projections for any product changes (e.yard., new launches, if you lot're retiring items, will exercise limited drops that sell out and don't get restocked, etc.).

- Look at market place share, including new competitors entering and exiting the space, forth with the current state of commerce in the markets you sell in (eastward.g., are at that place whatsoever COVID lockdowns in place, or is life back to pre-pandemic habits?).

- Create a timeline for inventory replenishment (e.grand., consider whatever manufacturer bug, if you're diversifying your supplier mix, or will take new lead times, fifty-fifty from ocean freight port congestion and other supply chain delays).

Planning for the unexpected and adding in a buffer for whatever unexpected publicity (good or bad) is wise — though information technology's too incommunicable to fully predict what will happen. Even so, it's best to run a few scenarios — conservative, average, and aggressive outcomes.

4. Make changes on the fly

Adjust the forecast as y'all go to continuously compare actual functioning with the forecast. Then reforecast as needed. Equally projections change, brand sure to go on all key stakeholders in the loop, from marketing teams to inventory leads (and of class tertiary-parties like manufactures, 3PLs, marketing agencies, and anyone else across your supply and need channels that should be in the know).

If you haven't nonetheless, be sure to set a reorder signal for each SKU. First, think through:

- Your maximum stock level for a given SKU (i.due east., what the inventory count volition exist in the pallet or on the shelf when it's completely total. If y'all take unlimited funds and inventory storage space, this tin be a higher number, or the infinite allotted for that particular SKU).

- As your stock depletes as you fulfill orders, y'all'll demand to furnish it. The unit of measurement quantity at which you lot create a new purchase order is the reorder point. The reorder point formula is non just a shortly-to-exist out-of-stock alarm, but rather a proactive and strategic stock level that takes several factors into account.

To calculate reorder points for your products, add up the following number of days:

- Your manufacturer'south lead time for sending inventory to you (AKA the number of days it takes to receive new inventory at your warehouse from ordering it)

- Your warehouse's or retail fulfillment company's inventory receiving turnaround time (if applicative)

- Your safety stock number of days in example suddenly spike in customer need or delay on the manufacturer'south end

Next, multiply the number you got in a higher place by your average inventory demand per day. This number is your reorder bespeak!

When a SKU's stock level drops down to the predetermined reorder signal, y'all'll need to trigger an alert so that your inventory planner is aware and can create a purchase club (using the reorder quantity formula).This all will depend on your manufacturing production bike and your inventory turnover rate, or how fast you sell through your products. For example, if you sell through your inventory quickly, you will repurchase new inventory more often.

All-time practices for inventory forecasting

Good inventory management lends itself to good inventory forecasting. Here are some fundamentals that can assistance your business organisation get the correct inventory forecasting process in identify.

Involve other teams

Inventory forecasting can't be done in a silo. Whoever owns information technology must involve all key stakeholders including operations, finance, marketing, product development, and more. Each group has a unique perspective and the input needed to create the virtually accurate forecast possible.

Accept notes and revisit them for future planning

Tracking order book isn't always enough. Sometimes y'all need to write annotations to add together context or not forget the reason for a modify in demand.

List out any upcoming flash sales, known holidays (including those impacting your manufacturer such every bit Chinese New Yr), and other events that may cause your sales or product cycle to either dull down or ramp up. This way, you can look back at your notes from the previous year(s) to plan for the next twelvemonth.

Information technology's important to note that if inaccurate demand forecasting was caused by something unpredictable (e.m., y'all got a surprise shoutout in a major publication, your product was in a glory's Instagram mail service, etc.), then you wouldn't necessarily project that exact same spike into your forecast.

However, if terminal-infinitesimal Mother's Solar day shoppers ended upwardly bringing in a lot of sales for your business, you tin utilise that information to expect a similar performance in May of next twelvemonth.

Employ your data

Before you can make up one's mind when to reorder inventory, you need to understand how your inventory has moved historically. Your past sales and inventory data should guide future decisions and assist you be proactive, not reactive. This manner, your inventory forecasting process can exist repeatable and use a consistent forecast menstruation.

View real-time stock levels

To accurately predict time to come demand, y'all demand authentic, timely data. Real-time inventory tracking lets you monitor bodily stock levels at any point in fourth dimension and helps you go on tabs on whether your estimates were precise or drastically off. If they were inaccurate, examine the root cause. Understanding why this happened will assist yous acquire from the by and adjust your forecast as you become.

"We have a Shopify store but practise not use Shopify to runway inventory. In terms of tracking inventory, nosotros use ShipBob for everything — to be able to track each bottle of perfume, what we accept left, and what we've shipped, while getting a lot more information on each gild."

Ines Guien, Vice President of Operations at Dossier

Cull the right software

Replenishing inventory at the correct time and in the right quantities tin can feel similar trying to solve an e'er-irresolute puzzle. Step ane is to centralize all of your data across sales channels. You won't go very far if your data lives in silos.

"Then many 3PLs have either bad or no front-facing software, making it incommunicable to go along rail of what's leaving or inbound the warehouse.

On the supply chain side, I merely throw in what we placed at the manufactory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what's incoming, what'southward at docks, and so on. I can come across all of those numbers in a few seconds, and it makes life so much easier."

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Brand certain the software you lot utilise has all of the functionality that makes sense for your business's size, product catalog, and complexity. Depending on your unique needs, it might be a standalone inventory forecasting tool or an end-to-cease fulfillment solution like ShipBob that notifies y'all when it's time to furnish inventory.

"Our favorite aspects of ShipBob'southward fulfillment software are the algorithm and analytics. ShipBob's analytics dashboard has a lot of valuable reports that testify our summit-selling states, guild revenue and costs, units sold, sales by SKU, days of inventory, SKU velocity, sales vs. inventory distributions showing where our customers are and where we're shipping from, and more."

Andrew Hardy, COO of Nature'southward Ultra

4 tools for inventory forecasting

Inventory forecasting can become increasingly more hard the faster your concern grows and the more products yous sell. Here are some inventory forecasting tool, models, and methodologies to help with accurate need planning.

i. Microsoft Excel

Even though you can practice some modeling with spreadsheets, Excel sheets are one of the worst ways to manage and forecast inventory because they correspond a static snapshot in time and are not continued to other tools or updated in real-fourth dimension. Inventory forecasting should be very dynamic, automatically pulling in data feeds from several sources for the most up-to-date information.

two. 3PL

Every bit your business grows and you need larger quantities of product to meet demand, it becomes more difficult and also more critical to go inventory planning correct. Many ecommerce businesses outsource fulfillment to a third-party logistics (3PL) provider, then they don't have to build the infrastructure, dedicate resources, and hire the workforce to manage inventory and logistics themselves.

Non all 3PLs have integrated software for society, inventory, and warehouse management, merely ShipBob provides all of this to aid brands forecast properly. Because 3PLs are so large, they can likewise help a business experiencing unplanned demand or rapid, explosive growth.

"We ringlet out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each calendar week. It'south really piece of cake to create new SKUs and restock existing ones using ShipBob's technology, which is especially important with high inventory turnover."

Carl Protsch, Co-Founder of FLEO Shorts

It's important to note that communication with a 3PL is cardinal — if you're expecting a fasten in demand, whether your brand is existence featured on a Television evidence or offering an ecommerce wink sale that can deplete inventory, permit them know ahead of fourth dimension and so they can program for it every bit well.

3. Inventory management software

If yous manage gild fulfillment yourself, or your 3PL doesn't provide the right software, there are inventory management solutions that also include forecasting tools. This lets you monitor the inventory yous have on hand and units sold per day, run reports to see which SKUs are your best sellers, and maintain an understanding of how your business concern is performing.

For example, y'all can view current inventory on manus by each fulfillment middle, as well every bit see if you lot have whatever inventory in transit:

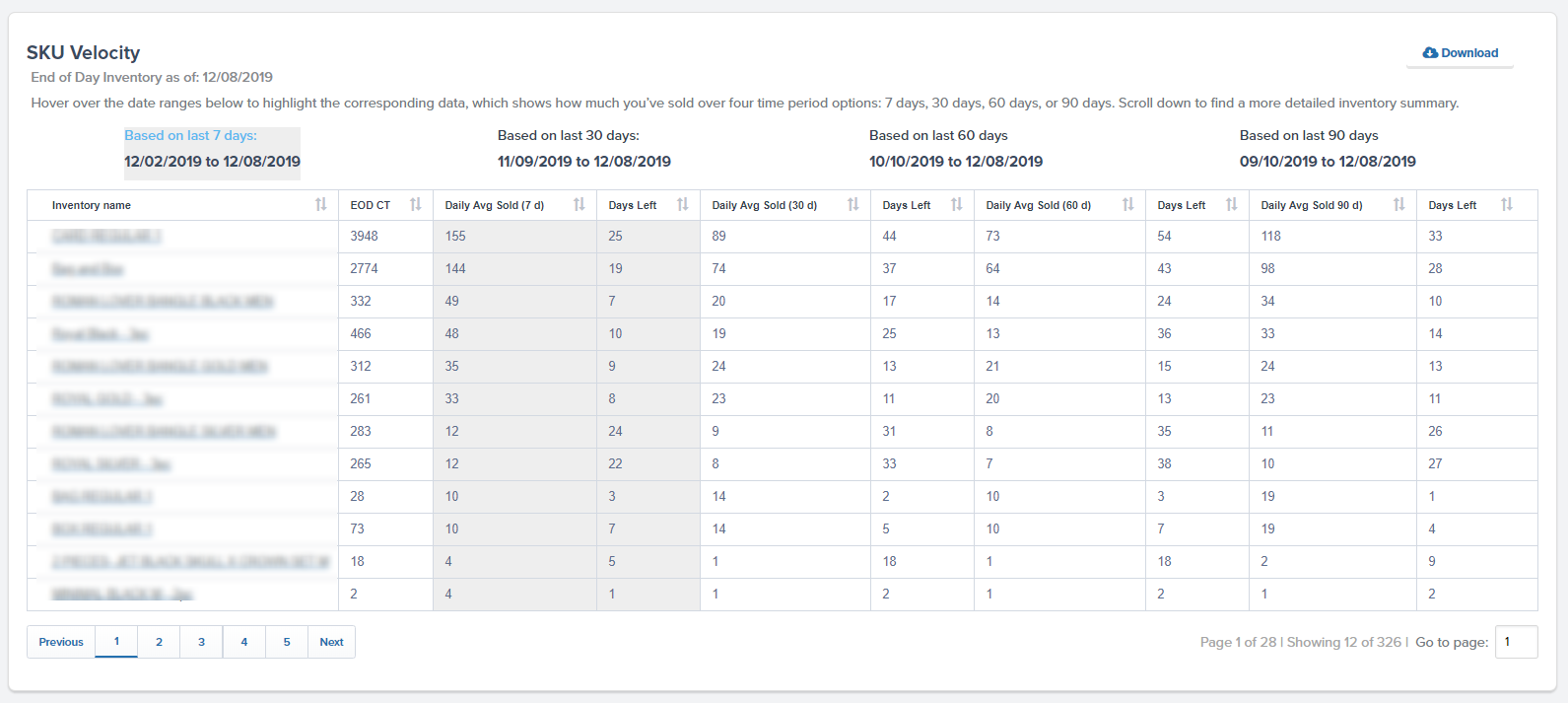

You lot also have admission to SKU velocity information to determine how many days you have left based on historical data, and then you can reorder more inventory on fourth dimension and avoid running out of stock:

"Ane of the greatest features of ShipBob'southward software is the inventory direction functionality, which lets the states runway inventory modify and velocity over time. Being able to monitor which styles are selling speedily helps united states ever keep our best sellers in stock."

Ryan Casas, COO of iloveplum

four. Inventory forecasting tools

Also 3PLs and inventory management systems, there are tools designed specifically for inventory forecasting with distribution metrics, information visualizations, advanced analytics, and inventory reports on sales and stock metrics. This helps you connect the upstream activities of purchasing and manufacturing to the downstream activities of sales and product demand.

"Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to have me hours. For every gild I placed for years, I was ordering too much or non enough. Between inventory forecasting tools and the ability to auto-create WROs, nosotros don't have stockouts much anymore. I sleep better at night."

Wes Brown, Caput of Operations at Black Claw LLC

Inventory forecasting in real-time for ecommerce

Thousands of ecommerce brands rely on ShipBob's fulfillment services but also love ShipBob's inventory forecasting tools to aid heave their ecommerce business. With ShipBob'southward analytics tools, you tin run across data that will help you plan ahead to make sure you are never out of stock.

Go information at your fingertips

Using historical data, ShipBob provides deep insights into your business through easy-to-understand metrics, charts, and reports, without the demand to build any reports yourself.

"I used to have to pull inventory numbers from three places everyday and motion all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-calendar month reconciliations. The enhanced visibility is peachy. With my quondam 3PL, I could never just open a page and go the info I wanted. I had to click several times, and so export information technology, and endeavor to make sense of it. ShipBob lets you lot manage your inventory while providing important data in a very digestible manner." – Wes Brownish, Head of Operations at Blackness Hook LLC

Measure SKU velocity

With ShipBob, you can exit-of-the-box reports, data visualizations, and inventory summaries, and change appointment ranges to:

- See how much yous've sold over dissimilar time periods.

- Calculate the expected days left until any item will be out of stock.

- Download reports to a .csv file.

"For inventory planning with ShipBob, I honey the SKU velocity report, daily boilerplate products sold, and knowing how much inventory we have left and how long it will last." – Wes Chocolate-brown, Head of

Operations at Blackness Claw LLC

"One of the greatest features of ShipBob's software is the inventory management functionality, which lets usa track inventory change and velocity over time. Existence able to monitor which styles are selling quickly helps us e'er keep our all-time sellers in stock. Nosotros've been able to get through our heaviest seasons while staying ahead of product using ShipBob's inventory forecasting tools — even as our society volume more quadrupled in less than a year."

Ryan Casas, COO of iloveplum

Understand your geographic distribution

Geographic distribution is elevation of listen for many brands that want to grow. Having analytics that answer the questions below helps brands optimize inventory placement and shipping to reduce transit times and aircraft costs:

- Where are my customers shipping to most frequently?

- Which shipping methods exercise my customers choose most often?

- How long does it accept my orders to be delivered by shipping method?

- Which states do I ship the most orders to?

- How should I distribute my inventory across ShipBob's fulfillment network?

- What would my shipping costs be if I went from one fulfillment center to two (or two to three, and so on)?

Enable integrations for seamless POs

On height of its congenital-in inventory forecasting functionalist, ShipBob has integrations with tools like Inventory Planner, Cogsy, and more to help brands streamline their supply chain.

"ShipBob'due south Inventory Planner integration allows us to have all of our warehouse forecasting and inventory numbers in one platform. We tin create ShipBob WROs directly in Inventory Planner and have the inventory levels be reflected in our local shipping warehouse and ShipBob immediately. Information technology also provides forecasting for each private ShipBob warehouse, so we know how many units we need to send each week to encompass a certain menses and besides to not run out of stock."

Marc Fontanetta, Managing director of Operations at BAKblade

These tools can exist relatively cheap and salvage your operations team lots of time.

"Some other ShipBob integration I love is Inventory Planner. It saves me hours every calendar week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours. For every order I placed for years, I was ordering besides much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, nosotros don't have stockouts much anymore. I sleep better at dark."

Wes Brown, Head of Operations at Black Claw LLC

Determination

When it comes to inventory forecasting, there is no crystal brawl. Even when you have the all-time tools to judge demand, at the end of the day, information technology is just that – an approximate. Simply continuously reviewing inventory turnover, stock counts, and other trends in your customer orders, you'll more accurately plan for both the curt-term and long-term.

If yous're in the market for a 3PL that can help you manage inventory and forecast need, check out ShipBob. With ShipBob'south thousands of customers, integrated engineering, fulfillment services, and ecommerce warehouses, you tin hands connect all the places you sell online to your inventory in our warehouses for a seamless ecommerce fulfillment experience.

"Off the bat, I liked that I would be able to control multiple warehouses through ane folio with ShipBob. With my old 3PL, I could never merely open a folio and get the info I wanted. I had to click several times, then consign it, and try to make sense of it. ShipBob lets you lot manage your inventory while providing important data in a very digestible way."

Wes Dark-brown, Head of Operations at Blackness Claw LLC

Learn more by requesting a price quote.

How To Optimize Inventory Using Weekly Data,

Source: https://www.shipbob.com/inventory-management/inventory-forecasting/

Posted by: mannbrainitterem.blogspot.com

0 Response to "How To Optimize Inventory Using Weekly Data"

Post a Comment